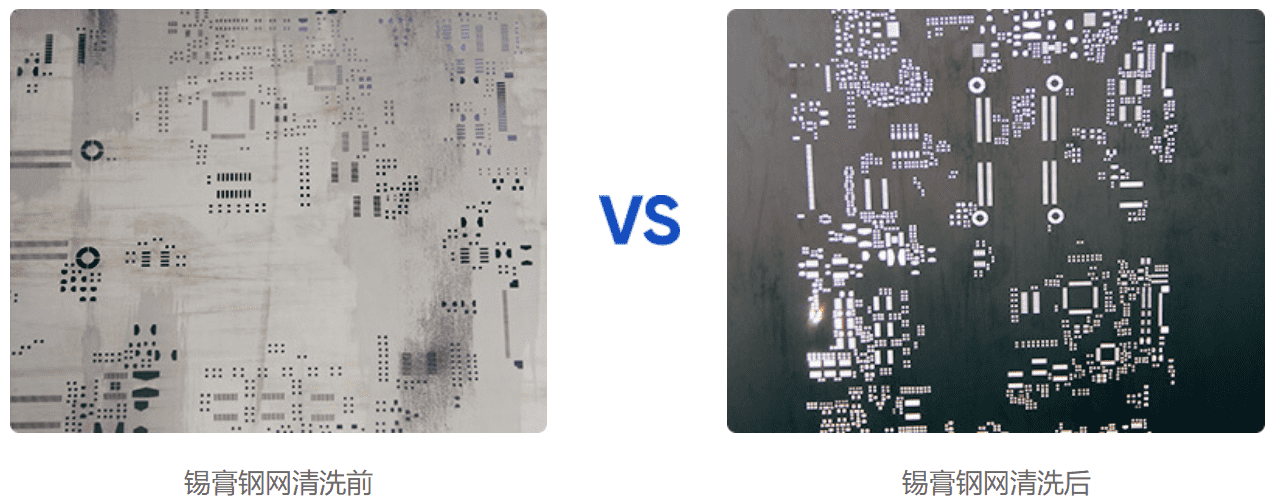

Unibright solder paste stencil cleaning advantages

1. Two phase water-based cleaning agents have high cleaning load capacity and excellent filterability, resulting in longer service life and lower maintenance costs. Using deionized water as a solvent is safe to use and does not require additional explosion-proof measures.

2. The formula is mild, with a pH of neutral, and has excellent material compatibility with sensitive metals, mesh plates, stretch mesh adhesives, plastics, and other polymers. It does not contain VOC components and can meet the relevant regulatory requirements for VOC emissions.

3. Low odor and minimal impact on the environment. No foam, meeting the requirements of high-pressure spray without foam.

4. It does not contain solid substances, does not require rinsing after cleaning, has no solid residue, and has no whitening phenomenon.

![[x]](/en/template/default/picture/closeimgfz1.svg)